Basically, the movement of rail freight continues using the Locos and wagons that are unchanged for over 50 years and in some cases 75 to 150 years. This is a stark contrast to the road freight industry that is constantly undergoing massive changes in configuration, haulage capacity, travel speeds, efficiency and safety.

The need to raise the rail share of freight movement is well recognised however, TfNSW is very reluctant to open up dormant but very capable rail lines, build new freight routes and importantly to introduce new rolling stock and consists to service these modern rail lines.

1. What is a 500 Tonne Train?

The 500 tonne train is a concept that would make old, unused, rail lines viable and greatly assist the mode shift from road to rail. It would be a mixed passenger / freight train based on the proven road train concept.

The train would have a maximum 500 tonne gross mass. The power unit would be like an extended road train prime mover with a passenger compartment capable of carrying about 30 passengers in car-like comfort.

The power unit would be capable of towing typically 5 wagons.

All the wagons would be standard NSW railways wagons with standard couplings. .

In practice the first wagon could be a 100 seat passenger car where necessary. It is likely that the other wagons would be container flat tops. The flattop wagons would be capable of carrying at least 1 FEU container and would be fitted with container pins.

2. How would it operate?

If consists like the 500 tonne train were to be operated on the re-established 210km former GNR line from Armidale to Wallangarra they would be operated on a high frequency basis making 16 return trips daily. This would allow for about 1500 passenger and 65 containers movements daily.

Containers would be moved from the train line with side loading container trucks for the first and last mile journeys.

Passenger journeys could include journeys to work, education and tourism. Health services, recreation and sport would also be important as passengers.

3. Why use a 500 tonne train?

The key issue in re-opening a rail corridor that has had little use for a period of time is the capability of the track and integrity of the corridor and its support infrastructure to allow trains to operate safely.

By restricting the gross weight to 500 tonnes, trains will be able to commence running with minimal track works allowing revenue to be generated at an earlier stage.

As maintenance and upgrade works are completed the trains operation gross weight can be permitted to rise progressively thus allowing conventional freight trains of 3000 tonne gross or heavier to operate in the long term.

4. Physical Details

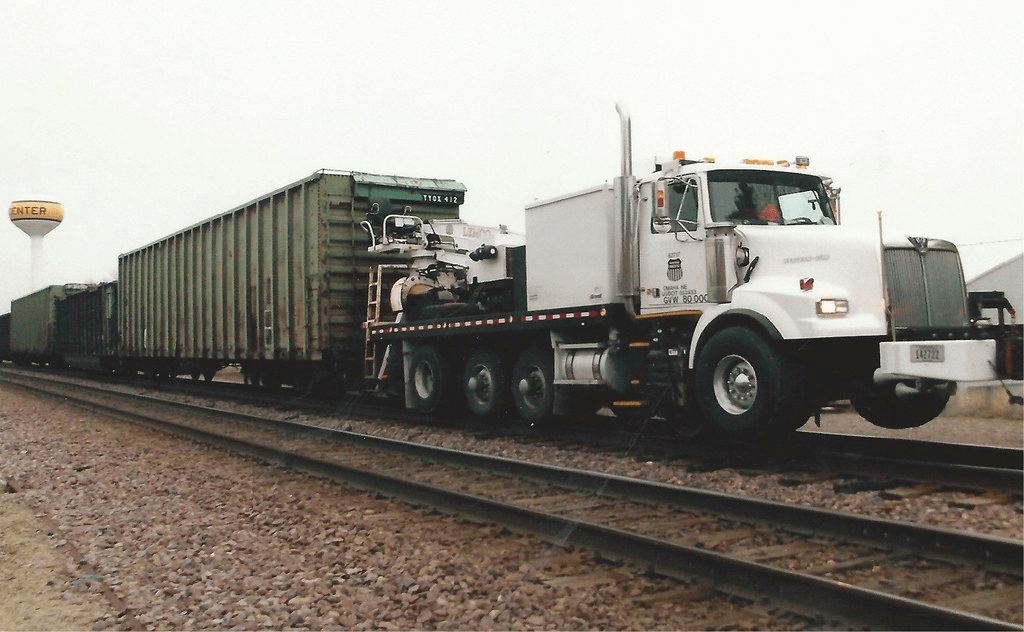

Australia has a unique vehicle know as a “road train”. It is a large heavy duty prime mover that tows 3 to 5 trailers and is capable of travelling long distances on rural roads.

Adapting a road train to run on rail tracks in rail corridors will provide a very useful unique train. The USA has trucks running on rail lines.

The prime mover would need two modifications: –

a) The wheels would be replaced with steel rail wheels.

b) The chassis would be extended into a long rigid version.

The prime mover would be a forward control version with the motor at the front like a traditional forward control truck.

Mounted on the rear of the truck would be a passenger compartment capable of holding about 30 passengers in air-conditioned car like comfort with forward facing seating and a fold down table with USB power, Wi-Fi connection, a cup holder and seat belts. The passenger compartment would have a food and drink dispensing machine and a cubical toilet.

The passenger compartment and driver area would be molded into a sleek quality rail design. Entry to the area would be from the rear via a ramp from ground level.

The prime mover would be fitted with the standard NSW railway couplings front and rear in order to allow the prime mover to tow and shunt most standard rail wagons.

In line with modern freight trends, it is likely that the wagon in highest demand will be the skeletal flat top wagon with twist locks. They will allow the transport of full and empty containers.

The use of containers will also minimise the freight handling needs of station or stops between Armidale and Wallangara,

It is recognised that the demand for passengers is likely to be much greater than the 30 catered for in the prime mover.

To meet this demand, it is likely that the first “trailer” will be a passenger car equipped to handle about 100 passengers in air-conditioned car like comfort with forward facing seating and a fold down table with USB power, Wi-Fi connection, a cup holder and seat belts. The passenger wagon would have a food and drink dispensing machine and a cubic toilet.

If passenger demand warrants, buses that run on rail tracks could be used with or without a trailer or trailers where the design permits. These buses would also be battery electric.

A combination of rail motors, normal freight train, the 500 tonne train and rail track buses would provide an amazing level of efficiency and flexibility and economy.

The size of the 500 tonne train and rail track buses would comply with the track and loading gauges of normal trains and be licensed as trains.

When fully loaded the 500 tonne train would have 24 axles giving a maximum axle loading of about 20 tonnes with a likely maximum speed of 80kph.

The 500 tonne train would be staffed by a train driver and a train assistant. The train driver would be responsible for the trains operation, including that it runs according to the schedule, makes the necessary stops for passengers and freight.

The train assistant would look after the passengers needs and assure that the dispensing machines were stocked and operational. The assistant would also assist with the coupling of wagons etc and operating the passenger platform and ramp.

Passenger ticketing and monitoring would be via Opal.

The conversion of the diesel power modified road train to a prime mover that is electric powered can be supplied by a Janus upgrade which could halve operational energy cost without the charging issues disrupting service delivery and largely eliminating emissions. Most battery charging would be by battery swaps and regenerative brakeing.

Each station would be operated by a caretaker who would be responsible for cleaning, toilet management and general duties.

The 500 tonne train would make 16 return trips daily transporting 1500 passengers daily and moving 65 containers. That would average at about 47 passengers and 2 containers per trip. The service would require 4 operational prime mover locos at a capital cost of about $2million each. Two side loaders and a tilt tray would be required at a cost of about $1m. Total Cost would be between $10m and $15m.

5.0 How would the 500 tonne train operate?

5.1 Passengers

Passengers would turn up at the station and electronically advise the train that they were present and then await the train. When the train arrives, the passenger would board the train and tap on via Opal and register their desired destination, automatically pay the fare then take a seat for the journey.

5.2 Freight

Via an app associated with Opal the freight forwarder would request the carriage of the freight to be consigned.

Details of the freight movement would be confirmed to all involved. A road truck (tilt tray or side loader) would collect the freight and take it to the agreed station at the appointed time. On arrival of the train the freight would be loaded directly on to the train and locked in place. The truck would proceed to the next job and the train would depart. The loading should take less than 5 minutes. At the destination the waiting truck would lift the container from the train and secure it to the truck.

Where appropriate the train could uncouple the wagon and proceed on its way. The empty wagon or full wagon would be picked up on a future passing.

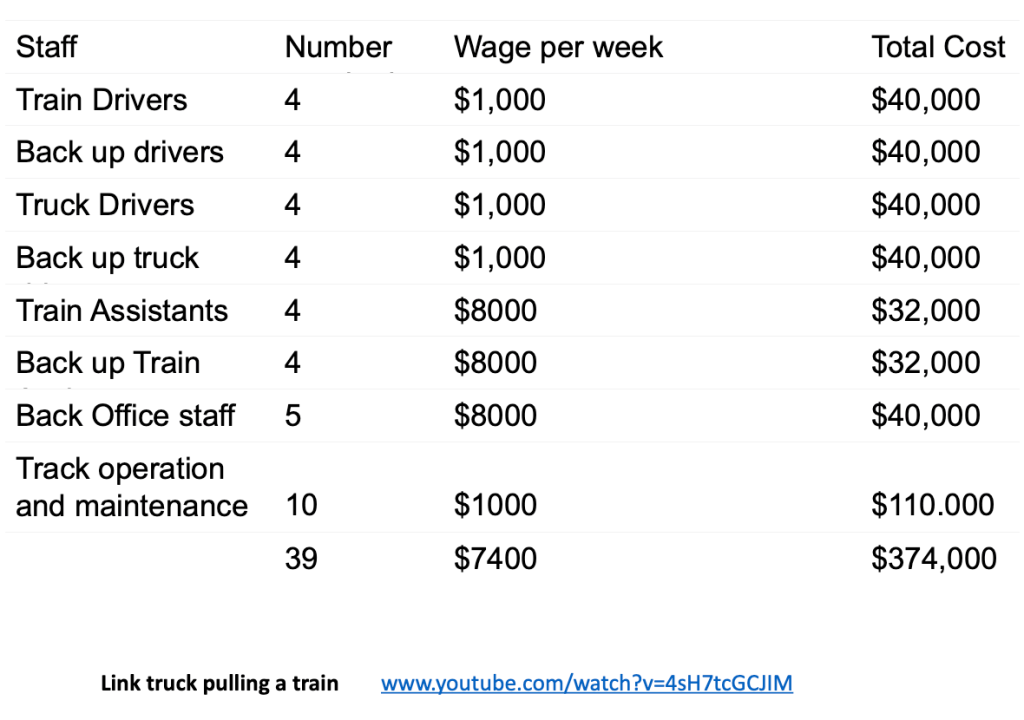

5.3 Staffing

The 500 tonne train concept is designed to be low in supporting staff numbers. The following table indicates the requirements as FTE. Positions.

Rick Banyard

Project Director

New England Transport Plan

1-may-2025